Norway – Aker Solutions is set to pilot the world’s first subsea power distribution system for floating offshore wind at Norway’s METCentre.

The project, marked by a front-end engineering and design (FEED) contract, aims to deploy innovative subsea power system technology capable of significantly reducing the costs and complexities associated with offshore wind farms.

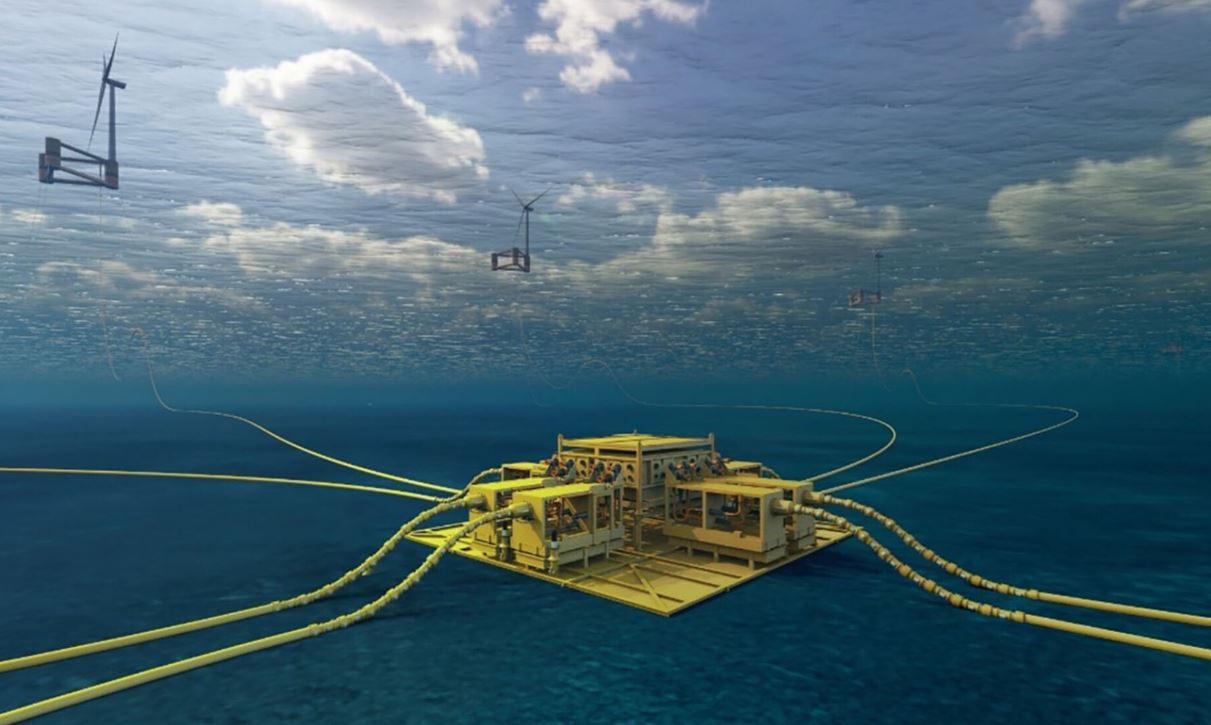

Aker Solutions will introduce the Subsea Collector, a novel power transmission technology, to the METCentre’s offshore wind test area, initially comprising two floating offshore wind turbines situated off the southwestern coast of Karmøy, Norway. The technology’s distinctive feature is its alternative solution for connecting multiple wind turbines electrically in a star configuration, deviating from the conventional daisy chain pattern. This design offers increased flexibility in offshore wind farm architecture and construction.

The Subsea Collector promises various advantages, including reduced cable length per turbine and park, lower vessel time, and decreased installation costs. Preliminary findings suggest potential total cost savings of up to 10 percent on a 1GW floating wind farm. The main components of the Subsea Collector include a 66kV wet mate connection system, subsea switchgear with supervisory control and data acquisition, and a static export cable to shore, showcasing collaboration with Benestad, ABB, and Windstaller Alliance.

Shaping infrastructure

METCentre’s decision to pilot Aker Solutions’ Subsea Collector reflects the potential of the technology to shape the infrastructure of large-scale floating wind parks.

The Subsea Collector’s development follows the success of similar technologies in large installation projects and Aker Solutions’ extensive experience in subsea power solutions, including applications in subsea gas compression and Equinor’s Hywind Tampen floating offshore wind project.