Germany – Salzgitter, in collaboration with ABB, is adopting ArcSave electromagnetic stirrer (EMS) technology to optimize the metallurgical performance of a new electric arc furnace (EAF). This initiative is part of the SALCOS program, marking a shift from coal-based to hydrogen-based steelmaking.

Salzgitter has set a target to produce virtually CO₂-free steel at its Lower Saxony plant in Germany by 2033. To achieve this, the company is replacing existing blast furnaces and converters with three electric arc furnaces (EAFs) and two direct reduction plants. The integration of hydrogen into steelmaking processes is expected to result in a remarkable 95% reduction in CO₂ emissions. This aligns with the International Energy Agency’s (IEA) recognition of hydrogen’s pivotal role in decarbonizing sectors with challenging emissions reduction scenarios, such as heavy industry and long-distance transport.

Primetals Technologies partnership

Salzgitter has partnered with original equipment manufacturer (OEM) Primetals Technologies for the Ultimate Furnace, a pivotal component of the SALCOS conversion. This EAF, with a tapping weight of 220 tons and an annual capacity of 1.9 million tons of steel, will initiate Salzgitter’s journey toward hydrogen-based steel production. The EAF Ultimate, known for its short tap-to-tap times, automated operation, and advanced control systems, will be optimized by ABB’s ArcSave technology.

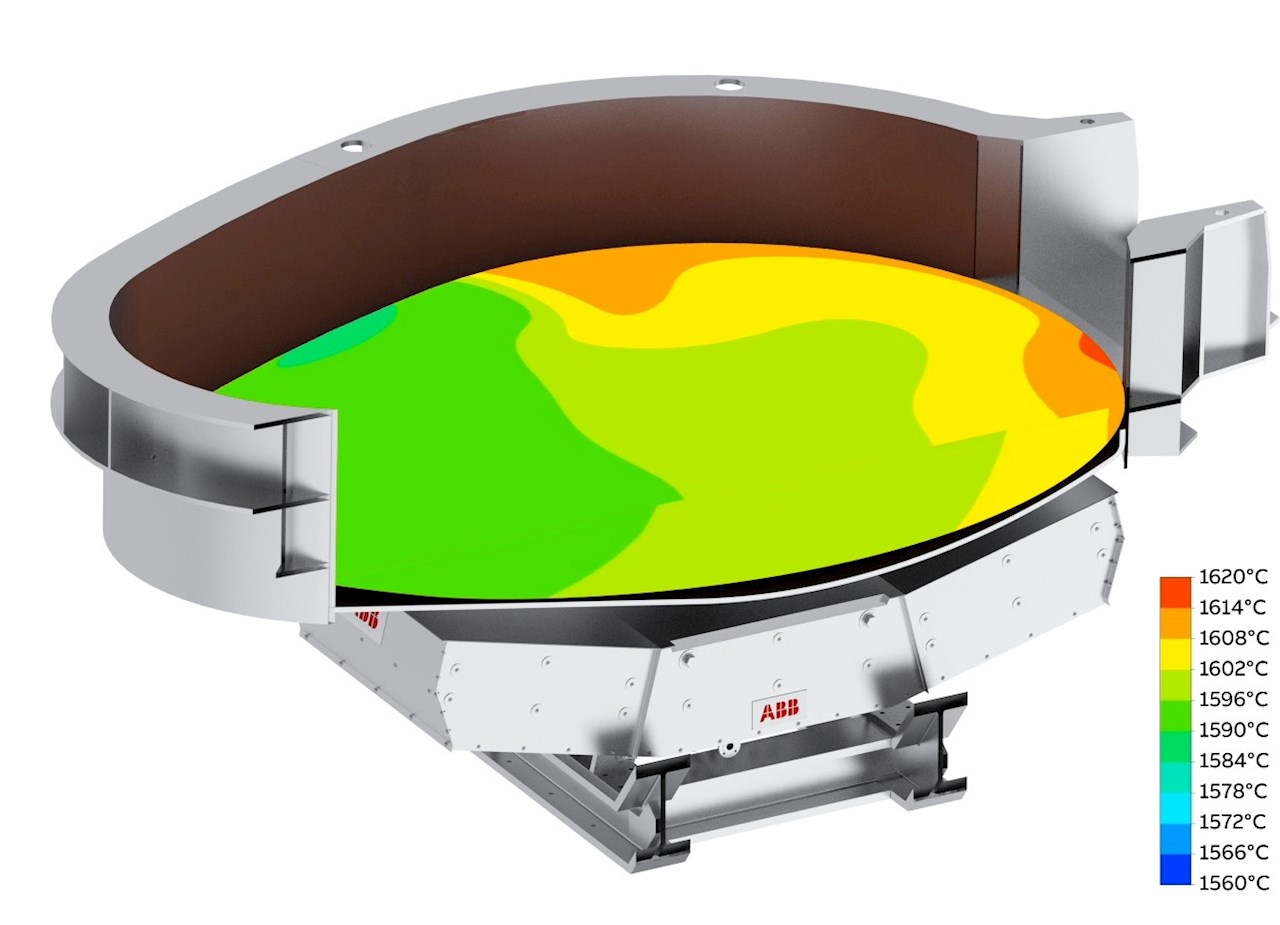

The ABB ArcSave electromagnetic stirrer will play a crucial role in optimizing metallurgical conditions within the EAF. This optimization is expected to result in higher productivity, lower costs, and a more efficient use of resources, including electrical energy.

The commissioning of ABB’s ArcSave technology at Salzgitter’s plant is anticipated in 2025.