Germany – Evonik is investing in a prototype electrolyzer at its Herne location as a starting point for the production of isophoronediamine (IPDA), a critical raw ingredient for rotor blades in wind turbines.

As part of a related study, Siemens Energy is investigating the potential of this innovative electrolysis process in an industrial chemical scenario. The collaboration began at the end of 2022 and will last through the middle of 2025. The Federal Ministry of Education and Research finances both investment and research programmes.

Judith Pirscher, State Secretary at the BMBF, says: “Green hydrogen is the missing piece of the puzzle for the energy transition. With the H2annibal project , we are therefore promoting research into innovative hydrogen technologies under real conditions in a chemical plant. This is how we accelerate the transfer from science to business and support the ramp-up of the hydrogen economy in Germany. The two projects are funded by the BMBF with a total of around 9.3 million euros.”

Renewable hydrogen

Evonik and Siemens Energy are leading the industry transition in terms of climate protection at the Hannibal colliery, where hard coal was mined until nearly 50 years ago.

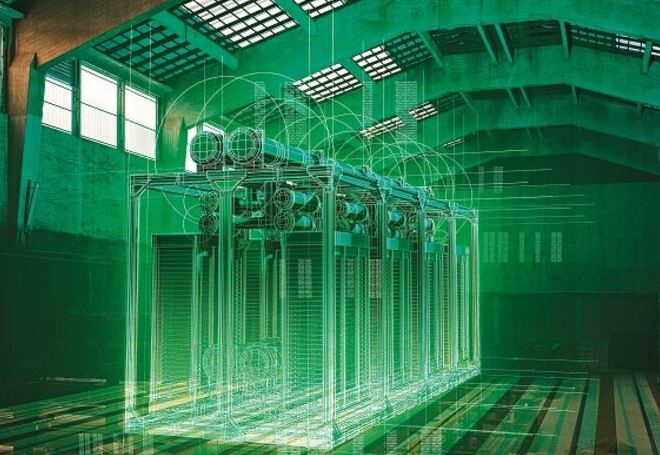

Evonik had previously relied on hydrogen derived from fossil sources at Herne. Future ambitions include on-site renewable hydrogen production. It is powered by an 8 MW Siemens Energy PEM (Proton Exchange Membrane) electrolyzer.

This is powered by renewable energy and can supply all of the oxygen required at the site, as well as up to 45% of the hydrogen required in the form of green hydrogen. During electrolysis, water is separated into hydrogen and oxygen using electricity. Running the electrolyser saves 12,000 tonnes of CO2 per year.