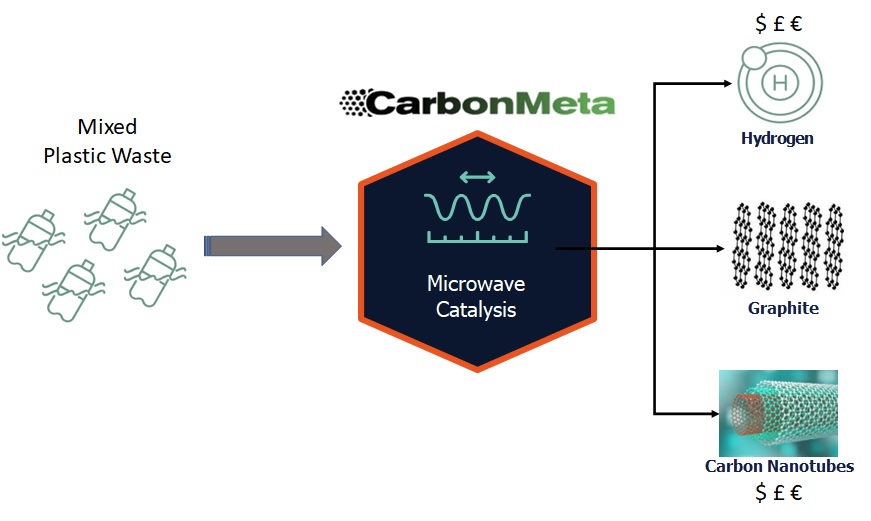

United Kingdom – The University of Oxford has developed a ground-breaking technology known as “microwave catalysis,” which CarbonMeta Technologies is commercializing.

The company has plans to process waste plastic at scale in specially designed microwave machines, producing high-value products for industry. One metric ton of plastic can produce enough hydrogen by mixing it with 200 kg of iron powder catalyst to heat about 200 homes. It can also produce 900 kg of graphite and carbon nanotubes, which can be used to make batteries for electric vehicles.

The process can take up to two hours to transform one ton of plastic, and the material can reach temperatures of up to 600 degrees Celsius.

Producing highest yields

To scale up this technology, the company is forming business relationships with international multi-energy providers in Europe. Its most recent project is an evaluation project in Spain that will examine how various mixtures of mixed plastic waste perform in the new process and how to produce the highest yields.

The use of batteries for electric vehicles and hydrogen for transportation or home heating will both be made possible by the technology. The outcomes of the European project will be made public in the fall of 2022, and subsequent commercial collaborations with potential users of the technology in the global energy sector are anticipated.