The Netherlands – ENGIE, OCI and EEW have partnered with the goal of deploying the HyNetherlands (HyNL) project.

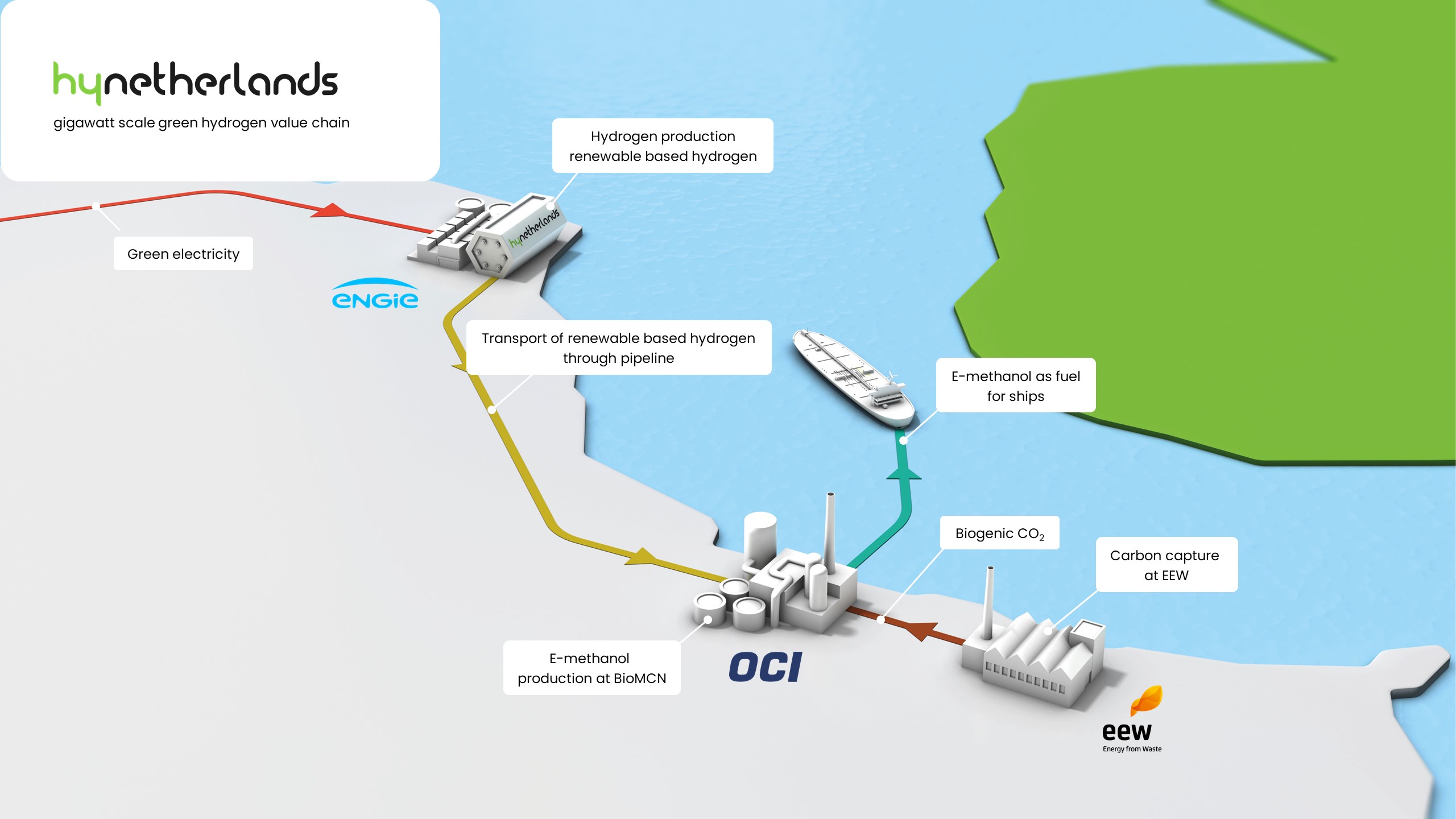

In the north of the Netherlands, HyNetherlands aims to develop, build, and operate one of Europe’s first large-scale industrial value chains for the production of e-methanol by combining renewable hydrogen and biogenic CO2.

Hydrogen and e-methanol are long-lasting, high-performance energy carriers that share many of the same characteristics as their fossil counterparts: high energy density, ease of bunkering and transportation, and the ability to leverage existing assets and infrastructure.

The project’s first phase will include a new 100 MW electrolyser facility that will produce hydrogen for e-methanol production as well as deliver renewable hydrogen to the local mobility and industry sectors.

Industrial sites

At three different locations, the HyNL project connects individual industrial sites. The ENGIE hydrogen production site in Eemshaven will be on the site of the Eems power plant. The 100 MW electrolyser will be powered by offshore wind turbines with a capacity of 200 MW.

The existing waste-to-energy plant in Farmsum will be integrated with the EEW carbon capture plant. It will capture biogenic CO2 from the plant’s production lines’ flue gases. Groningen Seaports will provide CO2 logistics and infrastructure on purpose.

The BioMCN methanol facility, located in the Delfzijl chemical park in Farmsum, can produce e-methanol by combining hydrogen and biogenic CO2.

The ENGIE (production) and OCI/BioMCN (offtake) plants will be connected to Gasunie’s hydrogen network, which is being built across the Netherlands and Northern Germany. The vast majority of the national hydrogen network will be made up of pipelines currently used to transport natural gas.

The project’s financial support and government approvals are top priorities. The project has already applied for grants from European authorities to this end (Innovation Fund). HyNL’s long-term goal is to play a bigger role in decarbonizing the region’s industrial and transportation sectors, with plans to increase electrolyser production capacity from 100MW in 2025 to 1.85 GW in the early 2030s.