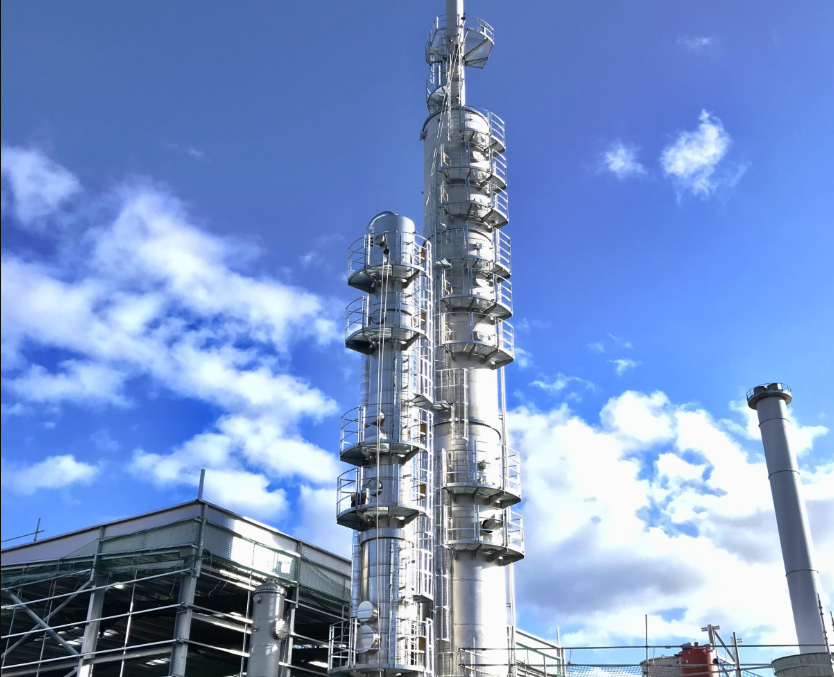

United Kingdom – The first industrial-scale carbon capture and utilization plant in the UK has been inaugurated by Tata Chemicals Europe (TCE).

One of Europe’s top producers of sodium carbonate, salt, and sodium bicarbonate, Tata Chemicals Europe, based in the UK, has completed the £20 million investment. The plant reduces TCE’s carbon emissions by more than 10% and captures 40,000 tonnes of carbon dioxide annually, which is the equivalent of removing over 20,000 cars from the road. As it demonstrates the viability of the technology to remove carbon dioxide from power plant emissions and to use it in high-end manufacturing applications, the project will aid in enabling the future of carbon capture.

Ecokarb

In a first for the world, sodium bicarbonate, which will be marketed as Ecokarb, is made using raw materials that include carbon dioxide that has been purified to food- and pharmaceutical-grade standards. Additional patents for this special and cutting-edge method are pending in several important international jurisdictions. More than 60 nations will import Ecokarb from the United States. In order to treat people with kidney disease, a large portion of the sodium bicarbonate exported will be used in hemodialyses.

The carbon capture facility, which TCE will use to produce sodium bicarbonate with a net zero carbon footprint and one of the lowest carbon footprint sodium carbonate products in the world, was made possible by a £4.2 million grant from the UK Department of Business, Energy and Industrial Strategy’s (BEIS) Energy Innovation Programme. Essential products like glass, laundry detergents, pharmaceuticals, food, animal feed, and water purification use these as raw materials.