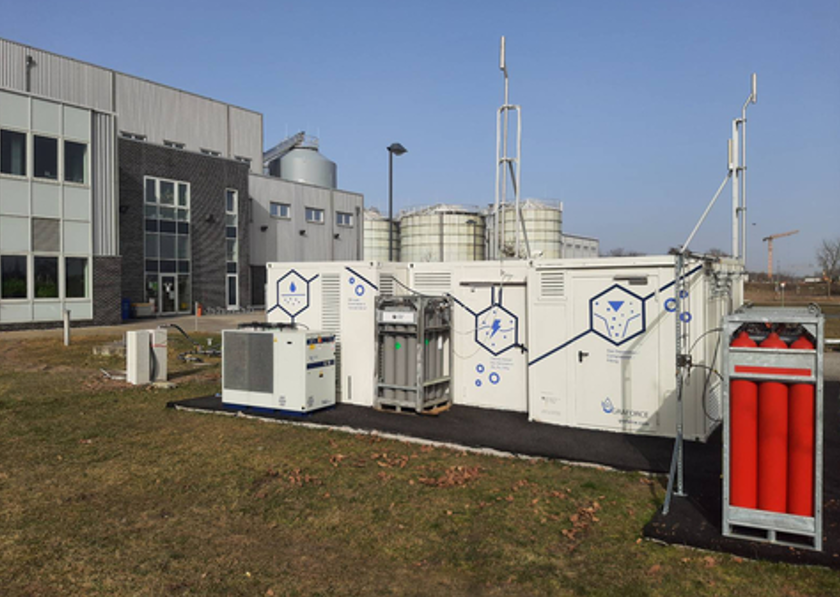

Germany – Graforce has developed a plasma electrolysis technology that can produce hydrogen from waste materials at significantly lower costs and yields.

In the mobility, industry, and decentralized energy segments, green hydrogen is expected to have a game-changing impact. It is critical to the achievement of global climate goals. By 2050, the global hydrogen market is expected to grow by a factor of six. Due to strong decarbonization commitments across sectors, Germany accounts for 20% of current European hydrogen consumption and is expected to remain the largest hydrogen off-take market in the EU.

Cost savings

Plasma electrolysis uses significantly less energy than water electrolysis to produce hydrogen, resulting in significant cost savings. Whereas water electrolysis requires 50kWh/kg H2, producing 1kg hydrogen from methane or wastewater requires only 10kWh or 20kWh.

Graforce collaborates with global leaders in engineering, procurement, and construction to develop and scale its modular plants to meet the needs of individual customers. To quickly scale its technology globally, the company is currently expanding its strategic partnerships with financial and strategic investors.